Closing the loop on Phosphorous in organic production systems

A review of eligible sources of struvite in the revision of the Canadian Organic Standards

Soil phosphorous (P) is an essential macronutrient responsible for plant life. It plays a vital role in most plant processes that involve energy and is needed in relatively high quantities for these processes to function effectively.

Much of the phosphorus used by farmers today is mined from phosphate rock. The mining of phosphorus is non-renewable, with some citing that there may be as little as 50-100 years left of the current supply. This is a looming threat for producers, especially those farming in areas with phosphorous-deficient soils. Once the mined phosphorus has made it onto the fields, it presents another problem for farmers and environmentalists. Contamination of waterways from phosphorus run-off contributes to eutrophication in water courses and can cause devastating algal blooms causing aquatic life die-off as the dissolved oxygen available to organisms is depleted. In some cases it can also produce toxins that pollute drinking water.

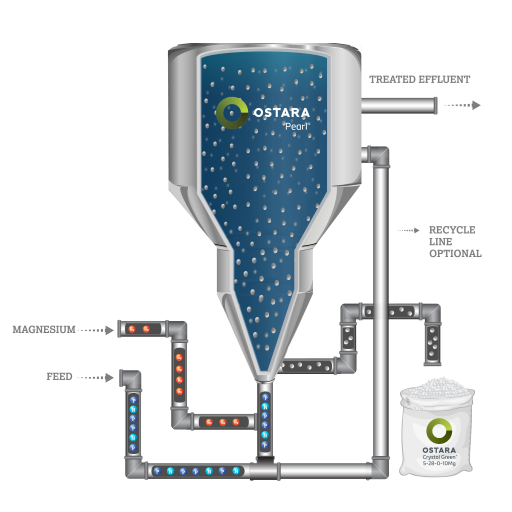

This is good news because the implications of using struvite recycled from wastewater is huge. Not only would this provide farmers with a recycled, renewable form of phosphorus, but the final product is low in heavy metals and salts, and has low water solubility, meaning that the potential for nutrient runoff which causes eutrophication in waterways is reduced. “It gives us a constructive way to start bringing some of the nutrients from our waste streams back into the organic community” says Ahren Briton, Ostara’s chief technology officer.

For many, the idea of using human waste derivatives in food production is unsettling, but Briton notes that the technology has come a long way. “There are real pathogen concerns; human manure contains human pathogens at a higher rate than animal manure does”. “Contaminants, such as trace organics and pharmaceuticals, are an issue […] the final product gets tested for the presence of these compounds”, Briton notes. “The technology has become far [more] advanced.” The crystallization process excludes foreign molecules from entering the structure, with a final wash step at the end to rinse away any potential surface contamination.

“The final product is assessed for the presence of those compounds – hormones, endocrine disrupters, antibiotics, and their breakdown products. We have found them to be consistently below detection limits in every case.”

Briton explains that part of the reason Ostara supports the OSC3 research activity is to show the safety and quality control work that has been done with struvite over the years. “We have a huge amount of data to support the chemical safety piece.” The method comes with multiple environmental benefits, both reducing the reliance of non-renewable resources while mitigating runoff to improve the health of waterways.

At the end of the day, the use of struvite sourced from municipal wastewater is less of a technical hurdle than a philosophical one. The approval of this product will be under review for the publication of the 2025 Canadian Organic Standards, bringing organic farmers that much closer to closing the loop of phosphorus nutrient recovery in a truly renewable way.

To learn more about Ostara Nutrient Recovery Technologies, their patented technologies, and available products, visit https://ostara.com/.

Find out more about Organic Science Cluster 3 Activity 26: The effects on soil biology, soil chemistry, and water quality of amending organically managed soils with struvite.

Read more about the phosphorus problem and use of struvite in the latest edition of the Organic Science Canada Magazine Spring 2022, where PhD Candidate Joanne Thiessen Martens discusses her research using struvite on farms in the featured article ‘Can Struvite Fix Our Phosphorus Problem?’